pompe si motopompe

GEHO

www.weirminerals.com/products/geho.aspxPumps with special design for handling high density and concentrations slurries over the long distances.

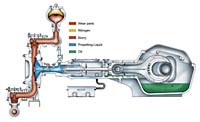

1. Electric driven piston diaphragm pumps

Capacity up to 1000 m3/h; discharge pressure up to 300 bar, solid particles size up to 6-8 mm, solid concentration up to 75% by weight;

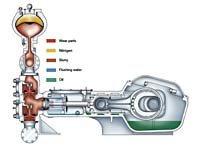

2. Electric driven piston pumps

Capacity up to 550 m3/h; discharge pressure up to 250 bar, solid particles size up to 6-8 mm.

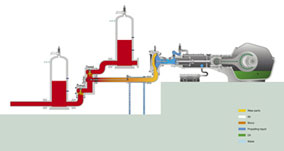

3. Hydraulic driven piston pumps

Capacity up to 150 m3/h; discharge pressure up to 120 bar, solid particles size up to 120 mm, solid concentration up to 90% by weight;

4. Heat barrier piston diaphragm pump

Capacity up to 550 m3/h; discharge pressure up to 70 bar, solid particles size up to 6-8 mm, temperature up to 2100 C.

Field of application:

1. Power industry :

Pumping coal burning residues (ash, slag, FGD products, etc.), as high concentration slurries to the deposit area. One single pump can handle slurries over long distances (kilometres).

2. Minerals processing industry

Autoclave and reactor feeding, digester feeding, tailings disposal and other similar applications consisting of pumping high dense slurries, at high pressures and temperatures.

3. Mining industry

Mine dewatering, by raising water with high solids content and highly corrosive to the surface, in one single stage. This eliminates costly settling ponds and high maintenance low efficiency centrifugal pumps.

Hydraulic ore hoisting: after crushing and grinding the ore and mixing it with mine water underground, the ore slurry is transported to the surface. Hydraulic ore hoisting is a viable, cost-effective alternative to skip hoisting.

Mine backfilling: whatever backfill system is applied, GEHO pumps provides reliable transportation of slimes or classified tailings. At the surface, the pumps are used for transporting slurry from the preparation plant. Underground, the pumps are used for filling the stopes with high density backfill, to stabilize the soil.